Polyurethane vs. Rubber Timing Belts: Choose the Best Timing Belt

Date: 2024-12-20 Categories: Industry News Hits: 245

Polyurethane Timing Belts vs. Rubber Timing Belts

Timing belts are essential in mechanical transmission systems, offering precision and efficiency. Among the options, polyurethane and rubber timing belts are the most common. Here's a comparison to help you choose the right one for your needs.

1. Material Composition

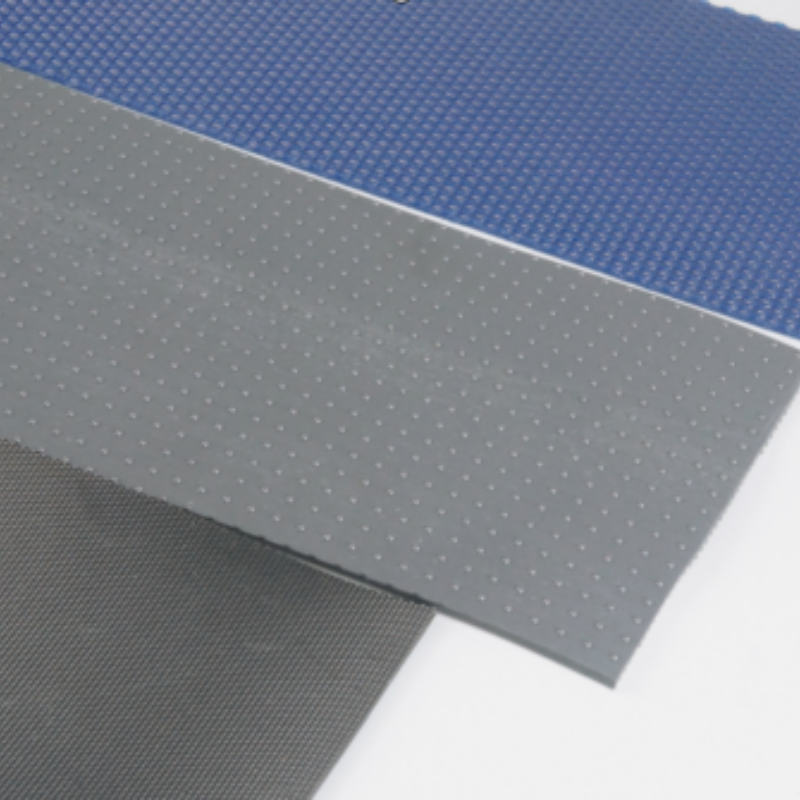

Polyurethane Timing Belts: Made from polyurethane (PU), they are durable, resistant to wear, oil, and chemicals, making them ideal for harsh environments.

Rubber Timing Belts: Composed of rubber, these belts are elastic and cost-effective but less resistant to wear and chemicals.

2. Performance

Polyurethane Timing Belts: Offer high transmission accuracy, stability, and efficiency with minimal noise and vibration.

Rubber Timing Belts: Provide moderate performance but may deform under stress, affecting accuracy and efficiency.

3. Applications

Polyurethane Timing Belts: Commonly used in high-precision systems like CNC machines and automation equipment.

Rubber Timing Belts: Suitable for light-load applications like household appliances and small machinery.

4. Durability and Maintenance

Polyurethane Timing Belts: Long lifespan and easy maintenance.

Rubber Timing Belts: Shorter lifespan and higher maintenance needs.

Conclusion

When selecting a timing belt, consider your system's precision, load, and environment. Polyurethane timing belts excel in high-precision, demanding conditions, while rubber timing belts are more budget-friendly for light-duty use.

ITASIA high-precision Pu open ...

ITASIA high-precision Pu open ...  ITASIA high-precision Pu open ...

ITASIA high-precision Pu open ...  ITASIA high-precision Pu open ...

ITASIA high-precision Pu open ...  ITASIA high-precision Pu open ...

ITASIA high-precision Pu open ...  ITASIA high-precision Pu open ...

ITASIA high-precision Pu open ...  ITASIA high-strength Pu sheet...

ITASIA high-strength Pu sheet...  Polyurethane seamless round ta...

Polyurethane seamless round ta...